SAP EWM BP558: How To Auto Pack and Print HU in SAP EWM Managed Warehouse

We are going to cover the EWM business process related to the Auto creation of HUs through Packaging Specification and Auto Printing of HUs through PPF Action for an Inbound delivery.

First of all, we need to configure the Packaging Specification for our Warehouse and we can refer to this BLOG for the same.

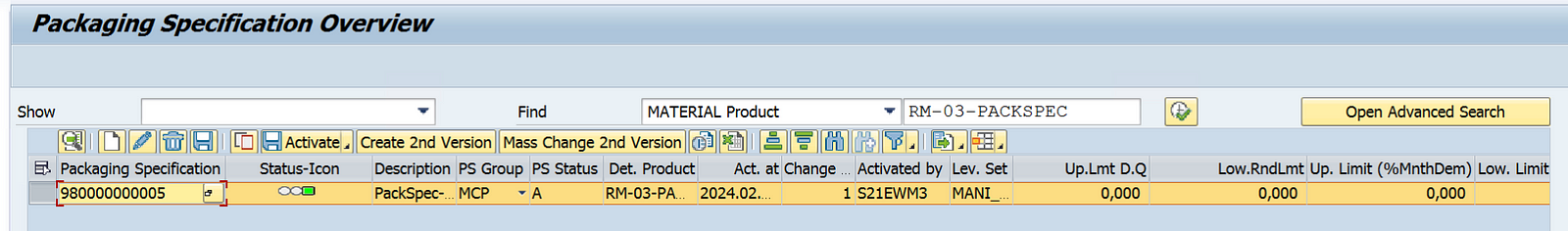

Once configuration steps are completed, maintain a multi-level PackSpec using Tcode /SCWM/PACKSPEC. We can also use the same setup for single-level PackSpec as well.

We need to maintain the condition record for our Product. Add the Product in the PackSpec and Add 2 levels. We need to maintain 2 Levels in the Level Set while configuring packaging specifications.

We have maintained 2 level types for our level set and each level type has a different element type.

Element Type CART was created for Carton and Element PALL was created for Pallet with Main packaging material as HU relevance.

Once this is done we need to activate the Auto Printing for our Packaging Material Type through PPF Action.

Step 1: Define the Action profile and Actions for the application.

IMG > SCM EWM > Extended warehouse management > Cross process settings > Handling Units > Basics>Print> Define PPF Action Profiles

Application: /SCWM/WME

Action profile: /SCWM/HU

Action Definition: HU_LABEL

Processing type method: /SCWM/HULABEL

Step 2: Now we need to define PPF Action Conditions

IMG > SCM EWM > Extended warehouse management > Cross process settings > Handling Units > Basics>Print> Define PPF Action Conditions.

Step 3: Define Print determination procedure.

IMG > SCM EWM > Extended warehouse management > Cross process settings > Handling Units > Basics> Print > Define Determination Procedure

Step 4: Assign the Print determination procedure to the packing mat type.

IMG > SCM EWM > Extended warehouse management > Cross process settings > Handling Units > Basics> Assign Determination Procedure

Step 5: Maintain Condition Record by using Tcode /SCWM/PRHU6 or /SCWM/DLVPPFC

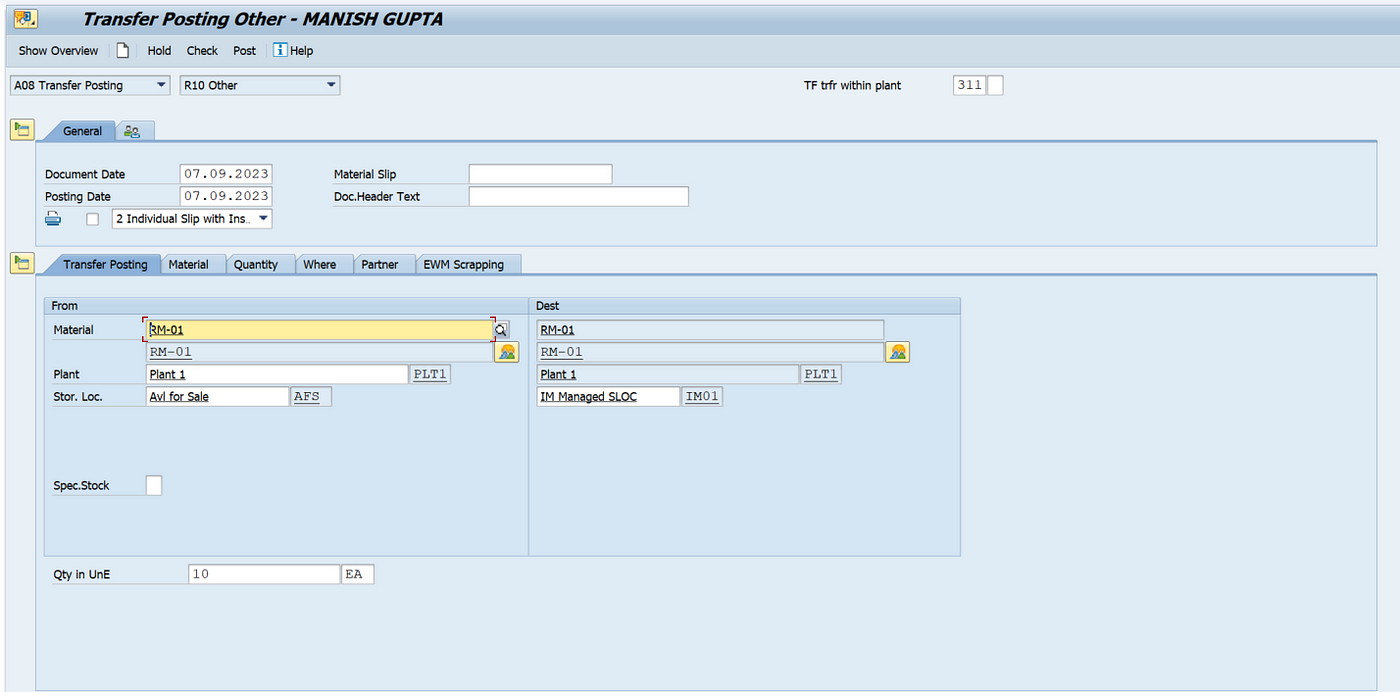

Also, It is important that we de-activate the option No Automatic Packing from the Delivery type for which we need to Auto Pack HUs.

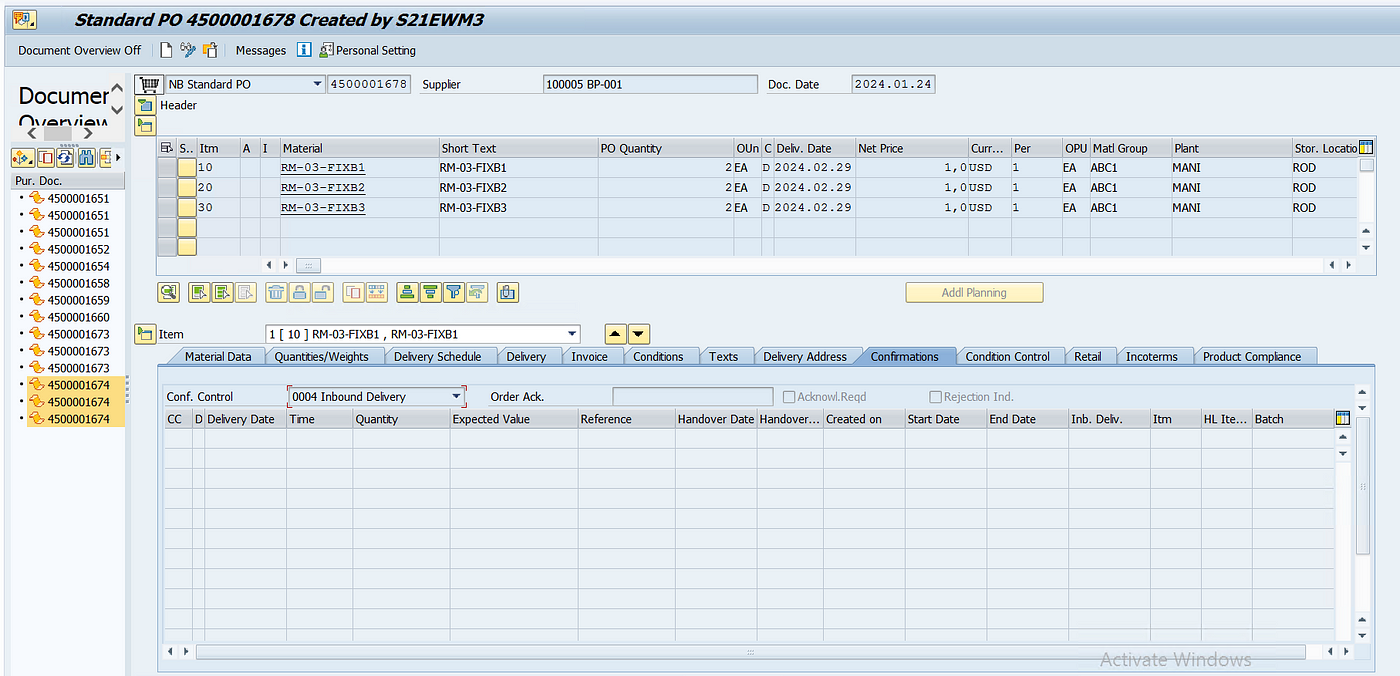

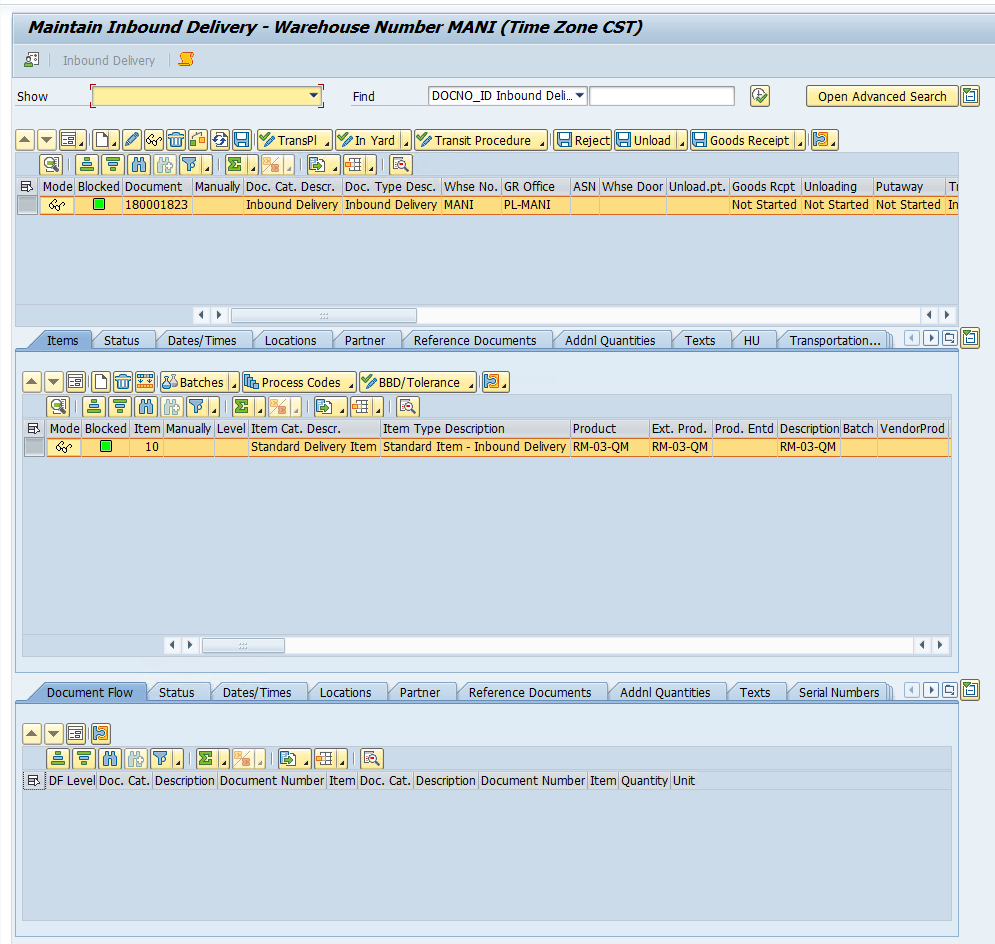

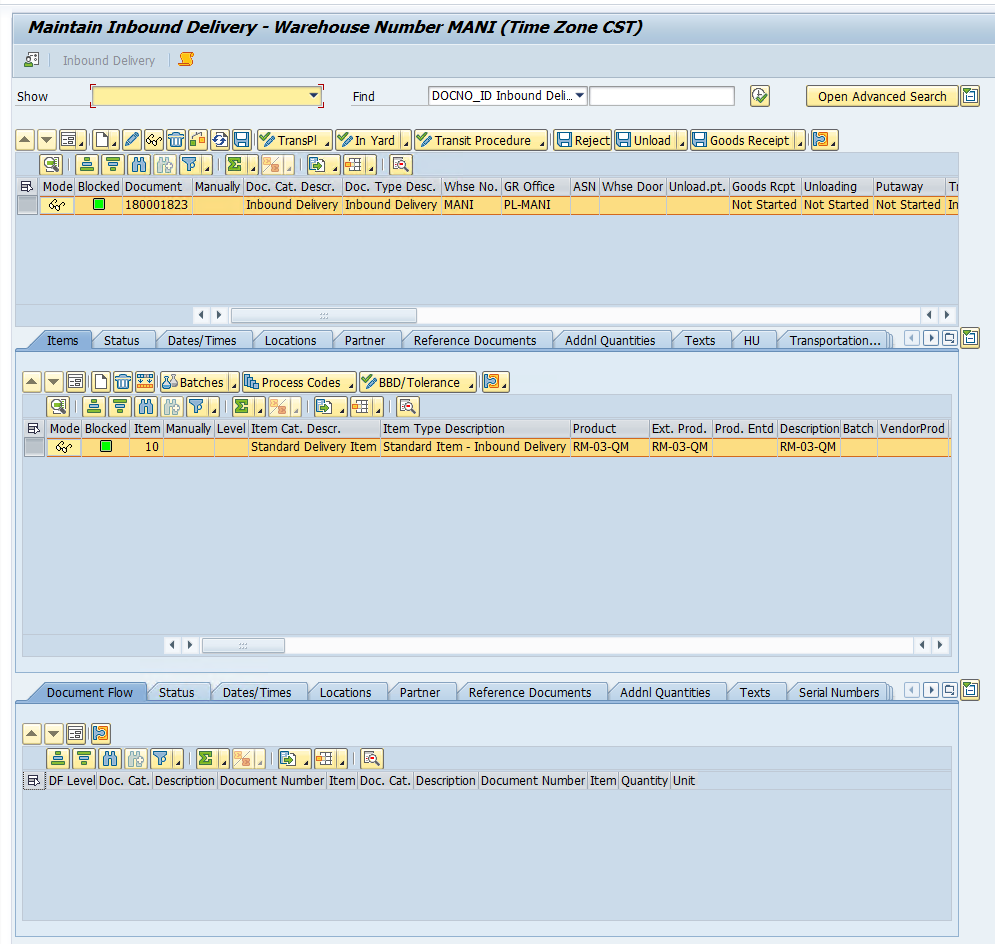

Now we will create an IBD in the S4 system and on successful distribution, HUs will get created automatically.

HUs will be auto-created in the EWM system and Print will get triggered in the background which we can check in SP01 Tcode.

Please feel free to reach out on LinkedIn if you have any queries or need help with your project.